It is learned from NIO and auto media AutoHome, in the early stage, in order to ensure a firm foothold in the high-end market, NIO implemented a full-stack self-research strategy, and established XPT NIO Drive Technology in 2015. Since then, XPT has continuously achieved innovative achievements in the core technology field of new energy vehicles, and has finally become an industry-leading technology company in intelligent power and three-electric technology.

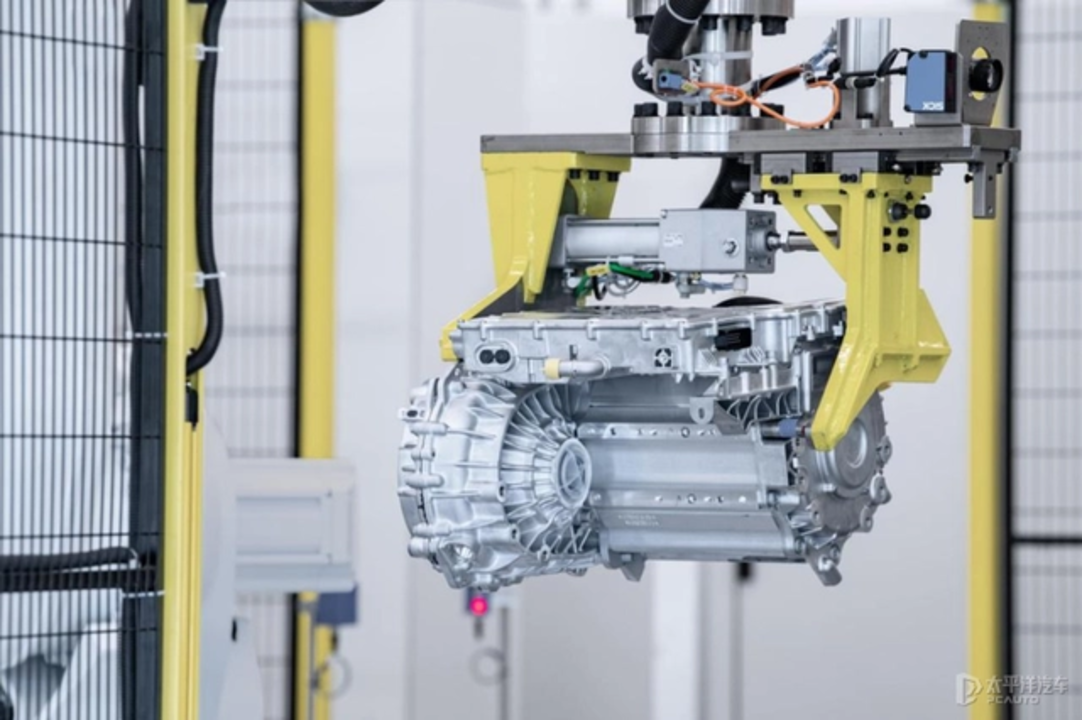

The electric drive system developed by XPT is a typical small-size, light-weight, high-performance electric drive system, which belongs to the first echelon in the industry in terms of design difficulty and various parameter indicators. The biggest innovation of this system is the use of silicon carbide (SiC) power modules as the motor controller. On the basis of keeping the size, weight and interface unchanged, the peak power and torque have been increased by more than 20%.

Nanjing, China 2021.06.22

At this stage, XPT NIO Drive Technology has achieved mass production of its self-developed electric drive system, and it has been launched together with the “775” models.

These improvements have been implemented in the actual experience, which means that the power and acceleration performance of the “775” model has been significantly improved. Among them, the intelligent electric flagship sedan ET7 has a 100-kilometer acceleration time of 3.8 seconds; The 0-100-kilometer acceleration time of the smart electric medium and large SUV ES7 is 3.9 seconds; the 100-kilometer acceleration time of the smart electric medium-sized coupe ET5 is 4 seconds. It can be said that the power and acceleration of NIO’s “775 model” are among the leading ones in its class.

In addition to enabling the “775” model to have class-leading power performance, this system also significantly improves the vehicle’s battery range and NVH performance. Specifically, XPT uses a new global control PWM algorithm to achieve a 30% energy efficiency improvement under different working conditions such as starting, accelerating, high speed, and heavy load.

In terms of NVH, XPT uses technologies such as EDS assembly modal optimization of mount fusion control, motor non-uniform air gap and high positive air gap flux density, gear shaft structure optimization design, and controller harmonic injection and control strategy optimization. The 5db-15db noise of the whole system is reduced, further improving the quietness of the vehicle.

In short, it is this electric drive system that directly gives the comprehensive performance and experience of the “775” a significant advantage over competing products at the same price.